Search This Supplers Products:steel flangesCarbon steel pipe elbowssteel pipe teessteel pipe redcuerssteel pipe capspipe bends

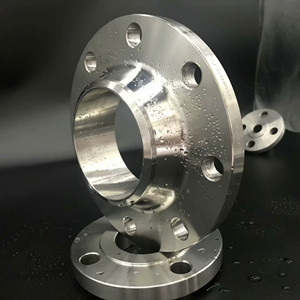

Forged Carbon Steel Flange

sourceJS FITTINGS

publisherLisa

time2021/09/24

- Carbon steel is the primary material of carbon steel flange and end flange connectors, common standards are ASTM A105N (SA105N), ASTM A350 LF2, ASTM A694, DIN 2533, and MSS SP-44. Pressure ratings from class 150 to 2500.

This extremely common and mild carbon steel is one of the most common of all. The material is extra tough, meaning it won’t break easily and is reasonably priced. This common carbon steel flange is seen in many industries and, with the help of lap joint end rings, is used in stainless steel piping systems.

The SA105N style is offered in 18” to 42” Blind Flanges, Weld Neck, Lap Joint, and SLIP-ON, in both classes 150 and 300. They can also be found in different classes and sizes with longer lead times – 12” to 60”.

There are several ways to manufacture the flanges, mostly are forging and casting.

As we know, the flange is a plate-like round device that is affixed at the end of a pipe, valve, fitting, etc. It helps in putting together a piping system. Manufacturers develop flanges of any material so that it matches the material being used for fittings and pipes. But mostly are two ways: Cast iron and forged in carbon steel.

A superlative mechanical property of any flange product is forged steel flange, which is made up of stainless steel, alloy steel, or carbon steel. Raw materials (mostly is pipe bodies) are cut and beaten to get rid of the block and defects. Compared to an ordinary casting flange, the cost and mechanical properties tend to be higher. A flange connects pipes to other pipes with a valve attached to the pipe end, which is also used for the flange on outlets and inlets. The link between the devices is what connects one pipe to the other. At the end of the tube is an alternative pipeline accessory.

The primary standards that have forged flange are American Standard, Japanese Standard, German Standard, Superscript, etc. Oil is the key anti-corrosion treatment, which improves temperature performance and forging flange pressure in both high temperature and pressure working settings.

a. Forged steel flange has better performances than cast iron flanges, lower carbon content so is harder to get rusty. Better shape with smooth streamline, higher mechanical strength because of the higher steel structure.

b. Forging process will not make a big or uneven brain, cost is higher than cast iron.

c. Forged steel is easy to be cut and can take higher tensile strength.

d. Casting iron could be made to different and complicated profiles, cost lower.

e. Cast iron steel exists air bubble, harmful defects, where forged steel flange don’t.

f. Use a Centrifugal machine will produce higher precision cast iron flange than normal cast flanges.

g. Forged steel flange could be used in higher pressure pipelines, where cast iron flange only could be used in non-pressure pipelines, otherwise will cause leaking problems.

How to prevent carbon steel flange from rusty

The carbon steel also will be getting rusty, so to prevent this, there are some solutions:

Electric zinc-coated (White or yellow zinc)

Anti-rust painting

Oil Varnished