Search This Supplers Products:steel flangesCarbon steel pipe elbowssteel pipe teessteel pipe redcuerssteel pipe capspipe bends

Differences between steel pipe bends and pipe elbows

Steel pipe bend is a bending pipe that used to change the pipeline direction. It is similar to pipe elbow, but differently, pipe bend is longer than elbow and usually manufactured for the specific needs.

So it depends on different bending radius (R) to distinguish bend and elbow.

In case the bending radius is more than 2 times of D (diameter), it is pipe bend.

In case bending radius in 1D or 2D, it is an elbow. (short radius elbow and long radius elbow).

How does the steel pipe bend make?

The pipe bend is bent by a set of bending equipment with two processes: Cold simmering and hot pushing. (Including bending, squeezing, pressing, forging, machining, etc)

Differences between Steel Pipe Bend and Elbow

Pipe bend and elbow both for change the pipe direction, still there are a lot of differences in the below aspects:

Bending Radius

Manufacturing Processes

Different cost

Application scope

Bending Radius of Bend and Elbow

As we talked above,

Steel pipe bend radius: Above 2 times of D, so there are 2D, 2.5D, 3D, 5D, 6D, 7D or 8D pipe bend.

Steel pipe elbow radius: R=1D or R=1.5D or 2D. Below 1.5D is a short radius elbow, and more than 1.5D but not over 2D is a long radius elbow.

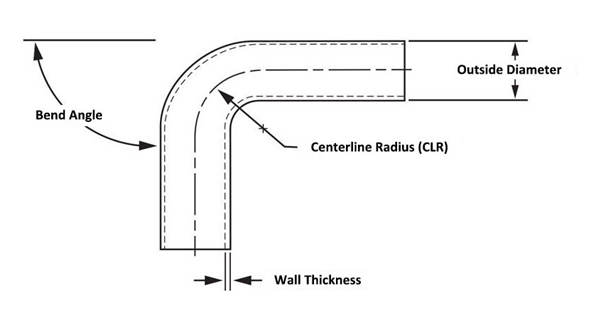

R is the radius of curvature; D is (elbow or bend) pipe diameter.

As the above picture, CLR could be in 1D, 1.5D, 2D, 3D, 5D, etc.

Different manufacturing processes

Bend: Could be bend directly from a finished pipe with cold bending processes, to different degrees.

Elbow: Shall be made according to standard manufacture procedures, with hot finishing or hot bending, to a certain degree, 45°, 90° or 180°.

Cost different

Professional manufacturer of asphalt machines. Our sales and R&D team have over 10 years’ experience to focus on asphalt distributor, synchronous pavement surface vehicles and other road machinery and equipment.

Different applications scope

Bend: Compatible with slower liquid and lower pressure.

Elbow: Compatible with high pressure and rapid liquid.

Sometimes elbows must be used in narrow sections because the radius of curvature of the elbow is small, generally 2D, but the pipe bend could be up to 40D.

We supply steel pipe bend with below ranges:

Manufacturing standard: AISI B16.49

Material: Carbon steel, Alloy steel, Stainless steel

Material standards: ASTM A234 WPB, WPC, WP1, WP5, WP9, WP11, WP22, WP91; ASTM A403 304/304L, 316/316L.

Outer Diameters: 1/2'' to 48''. DN15 to DN1200

Radius range: R=2D, 2.5D, 3D, 5D, 6D, 7D

Degree range: 45 degree, 60 degree, 90 degree and customized.

Wall thickness: SCH 10, SCH 40, SCH80